REACT3D

3D Printed Chemical Reactor Kit for Distributed Experiential Learning -

Capstone Project.

Project Overview

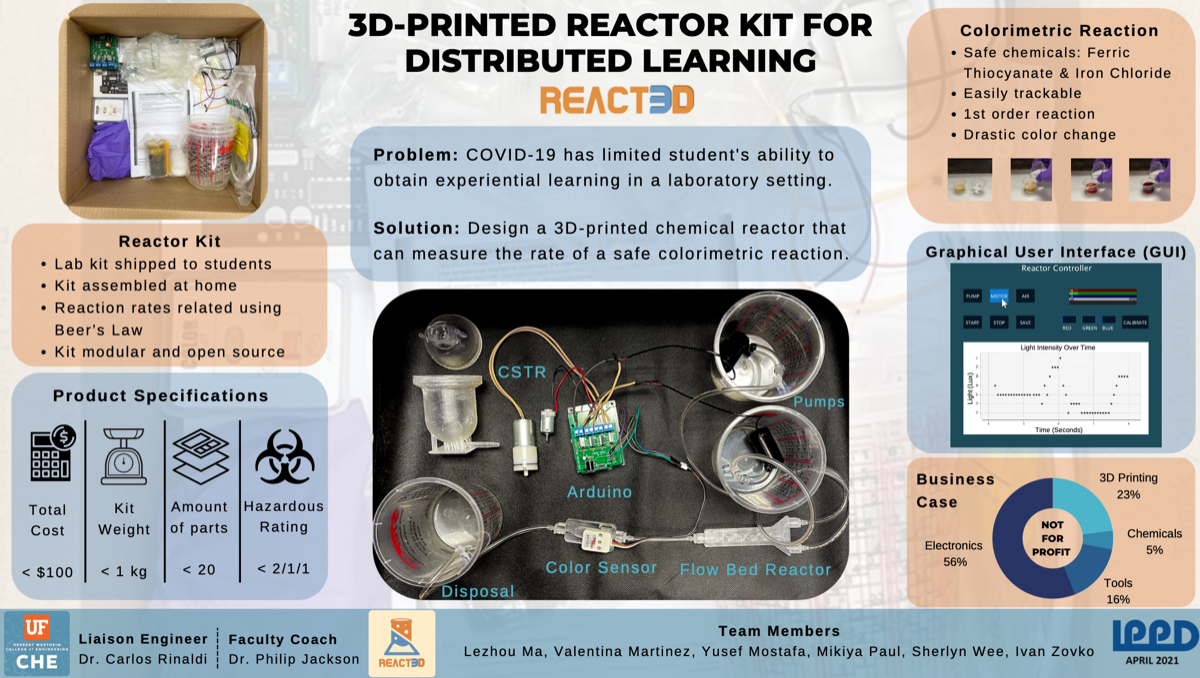

OBJECTIVE: Design, build, and deliver a low-cost 3D-printed chemical reactor kit that can measure the rate of safe colorimetric reactions for distributed experiential learning.

USERS: Students and faculty in the Department of Chemical Engineering, and high school students in the future.

TEAM: Six engineering students from mechanical engineering, materials science engineering, and chemical engineering.

Design Innovation

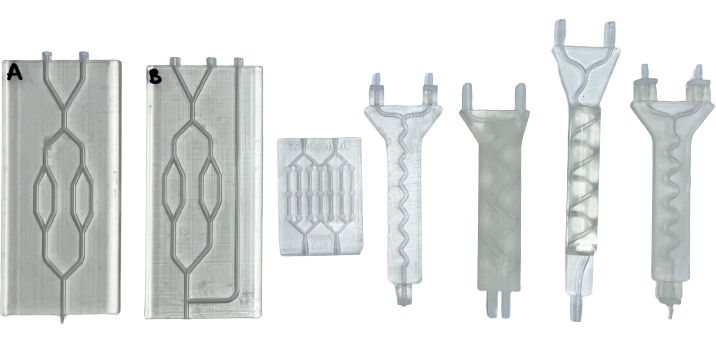

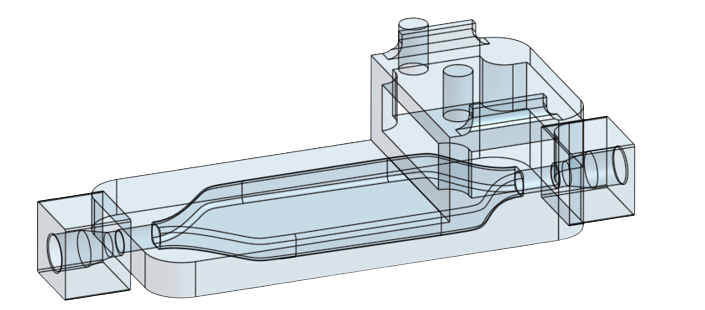

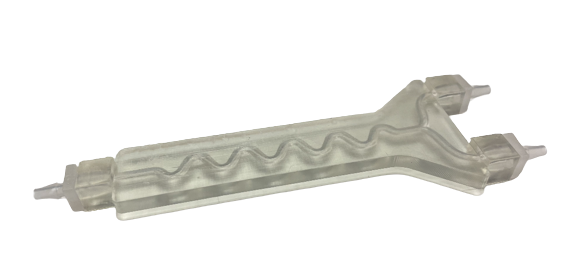

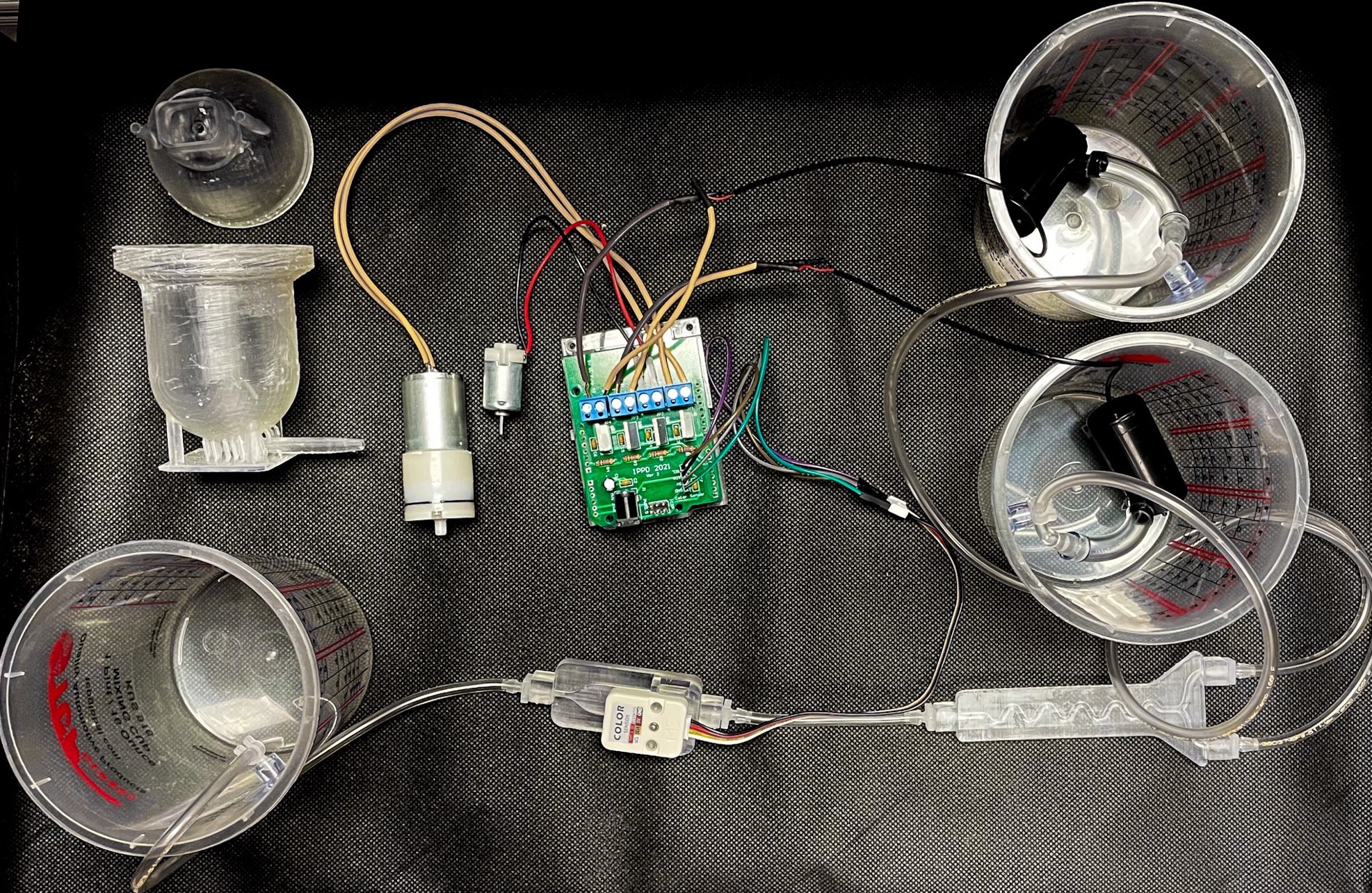

I led the design and prototyping of the reactor. In most cases, continuous-stirred tank reactor is used for performing colorimetric reactions; however, this kind of reactor is bulky and expensive to produce. From my research on the kinematics of passive mixing, I identified a channel shape that produced the same mixing capacity. The idea was to design a flow bed reactor where the channel would disturb the current and perform passive mixing.

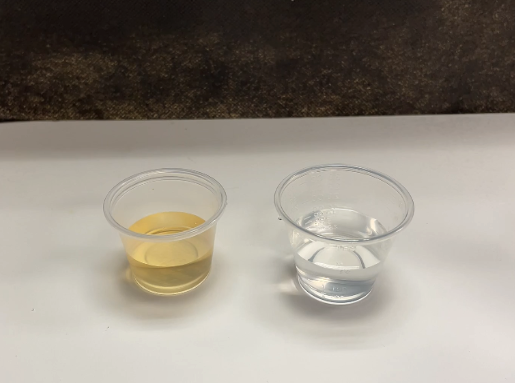

The images show the evolution of the flow bed reactors and the component for color sensing.

Purpose & Business Case

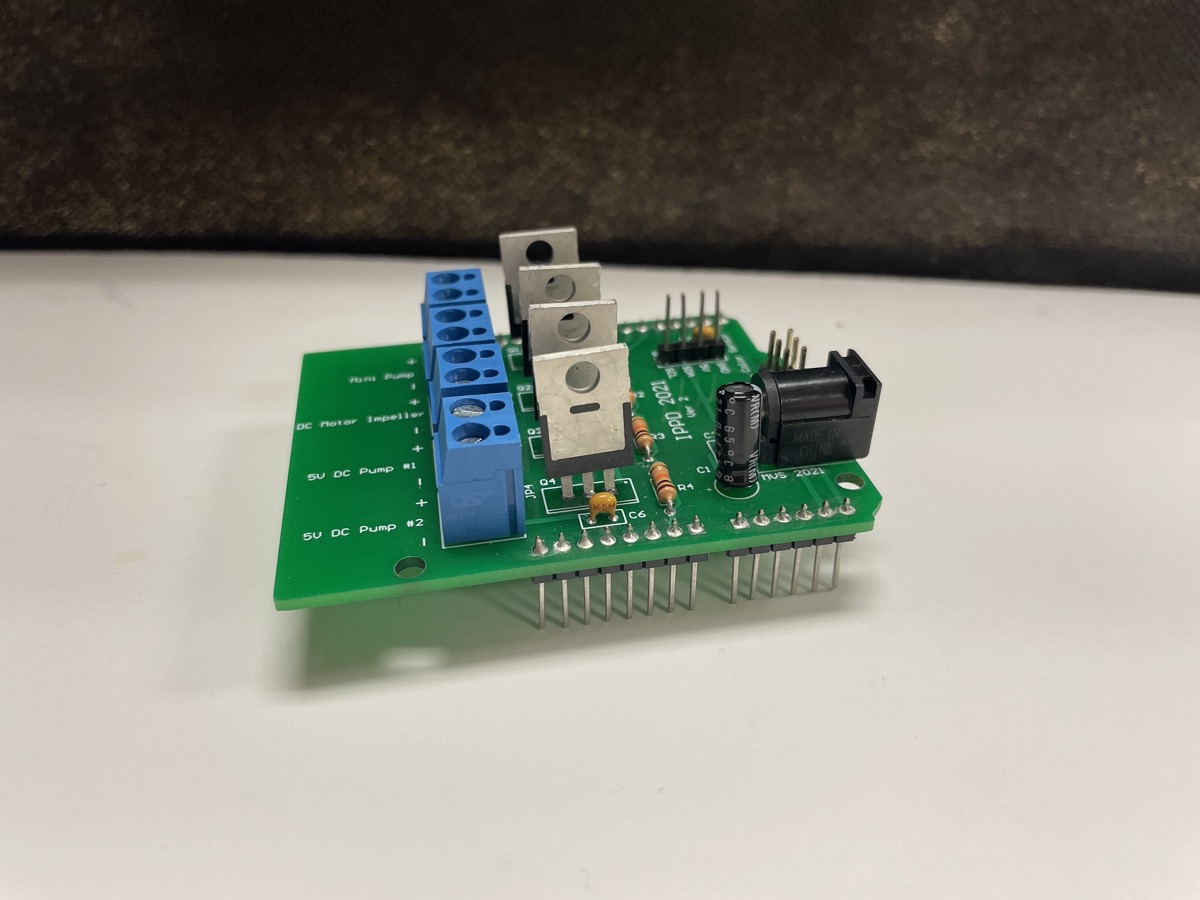

THE PURPOSE of this reactor kit is to provide students with the instructions and materials to conduct colorimetric chemical reaction labs safely at home. The kit consists of reactor parts, chemicals, pumps, motors, tubings, an Arduino, a PCB protoshield, and a basic GUI on the software side.

BUSINESS CASE: The BoM cost of the prototype was $98.88, under the $100 budget. Cost reduction could be achieved through wholesale sourcing. As a not-for-profit project, the cost for students to purchase the kit will reduce further when more are produced.